Data Migration and Conversion Strategies in Oracle E-business Suite:

Data Migration and

Conversion Strategies in Oracle E-business Suite

Businesses spend billions of dollars

migrating data between information-intensive applications. Yet up to 75 percent

of new systems fail to meet expectations, often because flaws in the migration

process result in data that is not adequately validated for the intended task.

Data migrations generally result from

the introduction of a new system. This may involve an application migration or

consolidation in which one or more legacy systems are replaced or the

deployment of an additional system that will sit alongside the existing

applications.

Whatever the specific nature of any data migration, the ultimate aim is

to improve corporate performance and deliver competitive advantage.

Especially while implementation of

Oracle e-business Suite and migration of the data from other legacy system to

Oracle

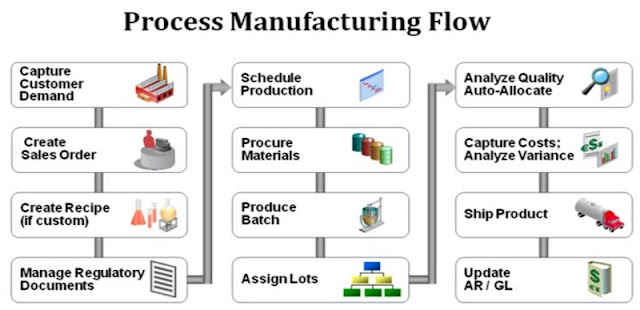

Steps To Design an Effective Data Conversion Process:

Below are the steps for

effective data migration and conversion process for any implementations in

Oracle ERP.

1-

Data Need for Conversion.

2-

Data Mapping / Conversion

Design

3-

Finalization of Data for

Migration

4-

Loading of data for QA

(Validation)

5-

Data Migration /Data

loading to Production.

6-

Data Validations -

Production

Data Need for Conversion:

The first

point is to decide which data is required for conversion and requirement. It is

normally depend on your implementations domain and modules. Which modules are implementing

during the imp mentation and that basis it is decided what is the requirement

of the data.

For example

it is Oracle Financials and SCM implementation and for that you need to load

the data from Financials modules let say for Oracle Fixed Asset data and from

Supply chain you need to load data for Oracle Inventory.

Data Mapping / Conversion Design

After

identifying the data for migration the next stage is to make the conversion

design and data mapping. Few are the important

points for data conversion design.

- · Extraction of data from Legacy System

- · Templates for data loading

- · Preparation of mapping sheet to map the legacy data to Oracle required data.

- · Field to Field mapping of data legacy to required data.

- · Legacy system data validation for mapping sheets.

- · Data conversion if required during mapping and validation

Finalization of Data for Migration:

Once the Mapping

is complete, the next step is to preparing and finalization of data for

migration. This step is very crucial, because whatever data is finalized and

migrated will be affected the performance of the ERP and it is saying garbage in and garbage out.

Each and

every aspect of the data should be reviewed and analyzed that every piece of

information that is required from the legacy data is available and converted

into Oracle required form.

Like for

Assets data for migration to oracle from legacy system, should be checked that each

and every information is included in the data sheets like Assets number, tag

number, Asset Category, Manufacturer, Invoice number, serial number etc...

Loading of data for QA:

It

increases the effectiveness of the data migration process. Data is loaded into

Test Instance (Sometimes called-QA Instance) for detail quality assurance.

Mostly QA teams are deployed on QA for data loading. But many cases the imp

mentation team validates the data when it loaded to Test Instance.

After QA it

identifies all the issues/ deficiencies of data uploaded then the same issues

to be resolved from the actual data before final upload.

Data Migration / Data loading to Production:

After data

validation the next step is data migration to Production. This step is

relatively straightforward. However, it would likely be quite time-consuming

due to the size of the legacy database.

Data Validations:

Once the

data is migrated to prod, the last step is to validation of prod data. Mostly this

validation is high level and summary level data is validated because detail

validation is done on QA (Quality Assurance) level.